Diacetyl Side Effects: What Are They?

One of the worst possible experiences for brewers, from home or in your own brewery, is off flavors. You go through all the hard work and trouble perfecting your recipe, sanitizing your equipment, grinding and boiling, steeping and pitching, only to have your beer turn… sour?

It’s a strange phenomenon that can be caused by several factors. Your beer turns out to taste and smell like baby vomit, sour milk, moldy cheese, or any combination therein. And you’re frustrated beyond all belief.

One of the contributing factors to this sourness is a compound known as diacetyl. Diacetyl side effects can be many, and they don’t always have to be scary. Indeed, you can carefully choose how much or how little diacetyl to have in your beer, and if you do indeed simply want to capitalize on it. The joy of brewing is that you almost always have options.

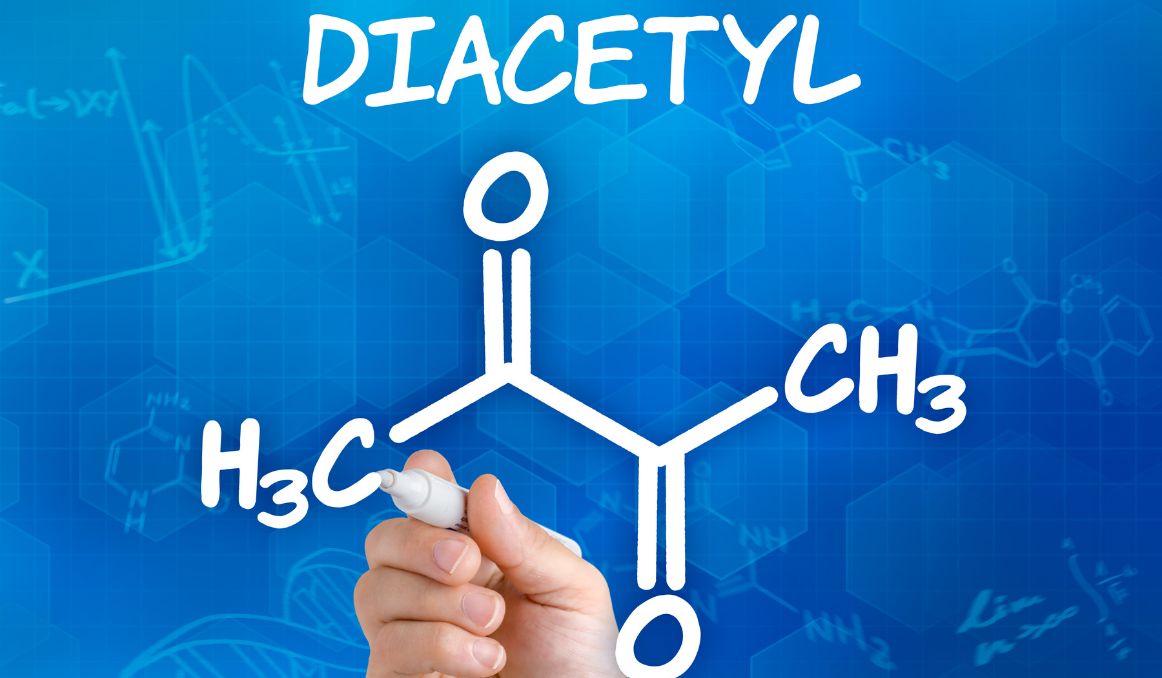

What Is Diacetyl?

Before we talk about how to capitalize on diacetyl, let’s talk about what it is.

Diacetyl is a compound found in food and drinks that contributes to the flavor profile therein. It gives foods and beverages a butterscotch like flavor in small increments and a sour milk flavor in too large quantities.

In beer, diacetyl typically comes from two sources: yeast or bacteria.

Diacetyl in Beer

Diacetyl is naturally occurring in beer and nothing to be afraid of. During the normal production of beer, you would follow the common steps: grind the malted barley or other grain, boil the ground barley, steep it, and then pitch the yeast.

The pitch is only the first of four stages yeast undergoes in its fermentation of beer: pitch, lag, exponential, and stationary.

Once you pitch the yeast, it enters a lag period where it is gearing up to reproduce and convert your sugars to alcohol and carbon dioxide. After the lag phase, it undergoes a period of rapid exponential growth. In both of these phases, yeast is building amino acids, proteins, and other cell components. One of those amino acids is known as valine. Valine is ultimately converted to diacetyl in the beer.

Diacetyl will change in quantity throughout the fermentation process because, while yeast produces diacetyl, it also comes back and consumes and converts it again.

The last phase of yeast, stationary, is when the yeast comes to a rest. During this period, it matures and the balance of flavors in the beer is corrected. This correction takes place as the yeast does a kind of self-regulation: it consumes a ton of the diacetyl in the beer, reducing it, and converting it to acetoin and 2,3-butanediol, both of which have very low flavor profiles, so are hardly detectable in beer. Much better than excessive sour diacetyl.

When It Goes Sour

Several factors can stop this last process from taking place with the yeast consuming the diacetyl and leaving you with off flavors you did not expect.

Temperature

Diacetyl is consumed more quickly at higher temperatures and more slowly at lower temps, so if you’re brewing a lager, which is fermented at colder temperatures, you will want to allow for more rest time for the diacetyl to dissipate.

Crashing

Some ale brewers make the mistake of crashing the temperature of their beer quickly to serve it, since it already tastes great and ale ferments quickly, without realizing that the diacetyl has not been consumed. They remove the yeast, which means the yeast can no longer consume the diacetyl, and they end up with off flavors days later. Take care that you allow even your ales a rest period so as not to end up with unexpectedly sour beer.

Yeast Strain

Some yeast strains produce higher levels of diacetyl, so you will naturally end up with a more butterscotch flavor in your beer. This is perfectly normal and acceptable, if it is what you are aiming for. Again, be sure you allow these beers to rest at the end, so you do not overdo the diacetyl compounds and take your flavor profile too far.

Contamination

Finally, diacetyl can also be produced by bacteria – Pediococcus and Lactobacillus, which are both regular contaminators of beer and nightmare invaders for home brewers and small breweries. You think you’ve got a great beer; then you bottle it, only to find it’s been contaminated days later when you open a bottle to drink it. To prevent this occurrence, ensure you sanitize well, bottle carefully, and leave a little yeast in suspension in your bottle to consume any remaining diacetyl.

Diacetyl Is not Dangerous

Rest assured, diacetyl is not dangerous. It is annoying and costly if you have to toss a batch of beer, but it is not the end of the world and will not make anyone sick. Indeed, diacetyl is present in a ton of food and drinks, and even welcomed at times.

The only time diacetyl is dangerous is in the inhalation of it, like in vape cigarettes. You have nothing to worry about in beer.

And again, remember you can experiment with these flavors, pitch new yeast to rid your beer of diacetyl, or even add another batch of beer to your off-flavor beer to help mellow out the sourness. Breweries around the world are playing with different flavor profiles, and diacetyl side effects do not always have to be bad ones.

The most important thing you can do is maintain a clean, sanitized brewing area, monitor your flavor profile throughout the brewing process, measure your gravity levels during fermentation to ensure you have reached peak gravity for your brew, and bottle carefully. When things go wrong, as they tend to do, you almost always have options. And when it comes to diacetyl side effects in beer, none of them are dangerous.

Cheers!

Passionate about the beer and/or wine making process? So are we! If you’re interested in finding out how you can use our technology to control fermentation and monitor your yeast, save work hours and improve the cost-efficiency of your business, drop us a line at [email protected] or check out our product pages:

- Oculyze BB 2.0 (Better Brewing) Yeast Cell Counter App + Hardware

- Oculyze FW (Fermentation Wine) Yeast Cell Counter App + Hardware

Also, you can now get access to a fully functional demo account to test our Web App. Completely free of charge and with no commitment to purchase.

Sources:

- Takashi Inoue & Yasushi Yamamoto (1970) Diacetyl and Beer Fermentation, Proceedings. Annual meeting – American Society of Brewing Chemists, 28:1, 198-208

- https://byo.com/article/brewing-science-controlling-diacetyl/