ISO Class Particle Count

If you’re in the business of building or needing a cleanroom, you may need to know about your ISO class particle count, how to determine it, and which level you need. While these concepts seem at first confusing and difficult to grasp, they are actually quite simple once you understand a few basic issues.

What Is an ISO Class Particle Count?

An ISO class particle count refers to the ratings developed by the International Standards Organization. This global group has established a system that rates the cleanliness of the air in a particular room. Cleanliness, in this instance, is a way of speaking about particle counts.

Particles in any given room can be microscopic, and there can be billions of them in a single room. As most people know, bacteria and yeast, the two most prevalent living organisms on earth, are present virtually everywhere. In most cases, this reality is just accepted as the way of life. In others, it can be detrimental.

ISO class particle counts provide us with an understanding of the concentration of particles in the air per cubic meter of space.

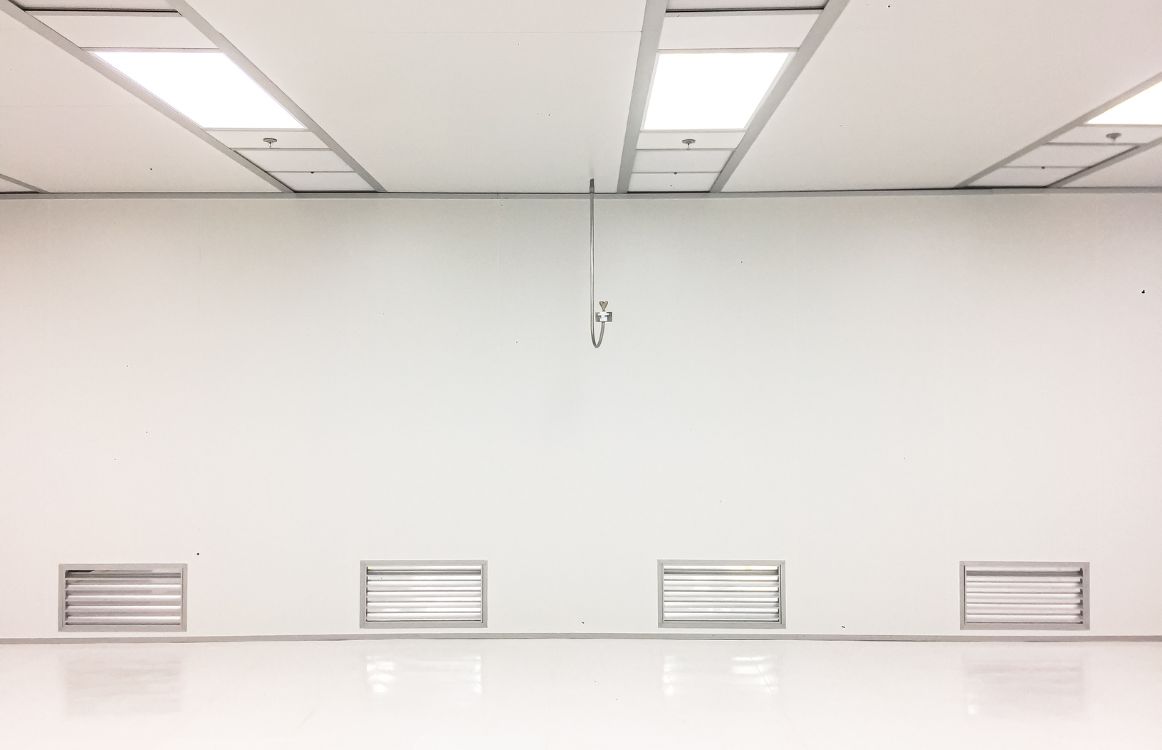

What is a Cleanroom?

A cleanroom is a space that has specific requirements in terms of how clean the air must be. There are levels of cleanliness expected for different uses, some demanding absolute sterility and others with looser expectations. The ISO class particle counter in this case would be an air particle counter.

Some air particle counters are handheld, which can be used by people who inspect cleanrooms and provide ratings. Other air particle counters are stationary units that will sit in a cleanroom and constantly monitor the number of microbes in the air.

For obvious reasons, the cleanrooms that must meet the highest standards will have stationary units constantly monitoring the fluctuations in particle counts. Those will lower standards but still in need of a higher level of cleanliness than the average room can rely on mobile units, either handhelds or those larger units that can be wheeled in and out of a room.

The absolute highest standard in cleanrooms is used for spaces where the manufacturing of equipment that will travel into space is performed.

Satellite dishes, rovers, and other machinery and technology that will be off-planet and potentially on other planets must have a zero-tolerance for microscopic bacteria or germs that may contaminate virgin spaces. We don’t want to destroy other living organisms in our zeal for exploration and discovery, which can certainly happen if we introduce bacteria from earth to alien organisms.

Other, lower standard cleanrooms can house the manufacturing of electronics and sterile items used in cleanrooms and the production and processing of food and agricultural products. Hospitals and laboratories that deal in biotech or life sciences are also typically cleanrooms, though these rooms often allow for higher particle counts as there is more room for interaction of particulate matter, though not much.

Pharmaceuticals are developed and packaged in cleanrooms. Gene, T-Cell, and MRNA research is done in cleanrooms. And medical devices are manufactured in cleanrooms.

Types of Cleanrooms

There also exist different kinds of cleanrooms. Again, for obvious reasons, the rooms that require the highest level of clean air, and therefore the lowest number of particles, must be constructed with hard walls that have no cracks or crevices through which particles may invade the space. Hardwall cleanrooms are easy to clean and make it easy to control the temperature and humidity, both major contributors to particle counts in the air.

In contrast, softwall cleanrooms are easy to construct, can be mobile, and therefore can be relocated when necessary. While you cannot have a cleanroom of the highest standard made with soft walls, you can still achieve a low enough particle count to allow for midlevel manufacturing and cleanliness.

How Are Cleanroom Ratings Determined?

The cleanroom ratings are determined by the ISO particle count chart. The range runs across classes, from ISO 1 to ISO 9, with 1 being the absolute cleanest and 9 being relatively close to an average clean room. To maintain cleanliness, an HEPA air filter is used in the room to pipe in clean air and remove toxins, contaminants, and other microscopic living organisms that can be harmful to the production, manufacturing, or packaging of machinery, equipment, devices, tools, drugs, electronics, or food.

In general, there exist very few ISO 1 rooms, and even ISO 2 rooms are few and far between. In the United States, the highest standard of cleanroom is typically rated an ISO 3, which allows for 1,000 particles per cubic meter, and this is on the nanoparticle scale, meaning those particles can be as small as .1 microns. It is for this reason that there are so few ISO 1 and ISO 2 rooms as we have only in the last couple of decades developed the technology that will enable us to identify nanoparticles in the air.

You can look up the charts illustrating how particulate matter allowed for each class level and how it has changed as we have gained the ability to recognize smaller and smaller particles in the air.

Particle counting – a solution

There is a constant need for particle counters, far beyond just cleanrooms, and there are countless applications for a generic particle counter.

Using image analysis and pattern recognition, the Oculyze Particle Analyzer can be customized to your specific needs. If a specific detection is needed, the system can always be expanded and combined with a classification to differentiate what is being counted.

You can give the Oculyze system a try yourself.

All you need are some images of the particles to be counted / detected.

Just please note that the recognition provided here is solely for demonstration purposes and may not accurately represent the performance of our product. Our customers receive customized recognitions tailored to their specific needs, which ensures high levels of accuracy.

Additionally, Oculyze allows you to keep all of your information in one efficient system designed to aid you in accurate and specific particle counting.

Summing It All Up

In the end, ISO class particle count is critical to the maintenance of cleanrooms, and those in need of clean rooms can always use help to keep those rooms clean and to understand how to read the data provided by air particle filters.

Sources: